Chemometrics

Non-Destructive Sensor-Based Prediction of Maturity and Optimum Harvest Date of Sweet Cherry Fruit | sensors LINK

IDC unveils its Top 10 Predictions for global Robotics Industry Industry40 Robotics LINK

Spectroscopy

Global Molecular Spectroscopy Market is expected to reach USD 6.712 billion till 2024. htt… LINK!

Near Infrared

Assessing pre-harvest sprouting in cereals using near-infrared spectroscopy-based metabolomics LINK

Rapid screening of commercial extra virgin olive oil products for authenticity: Performance of a handheld NIR device LINK

Hyperspectral

Imec () launches TDI, multispectral and hyperspectral sensors | imaging HSI LINK

Near-infrared hyperspectral imaging of lamination and finishing processes in textile technology LINK

Spectral Imaging

Viavi Solutions and ESPROS Photonics Corporation Debut New Miniaturized Spectral Sensor and Multispectral Sensor LINK

Equipment

Meta-lenses bring benchtop performance to small, hand-held spectrometer - Science Daily LINK

Scan anywhere with Neospectra Spectrometer Case powered by XPNDBLS PhotonicsWest … LINK!

Agriculture

World feed production exceeds 1 billion MT LINK

Chemometric soil analysis on the determination of specific bands for the detection of magnesium & potassium by ... LINK

Other

This app uses spectral analysis to analyze objects and their makeup HawkSpex LINK

Research details developments in the multivariate analysis software industry | MVA LINK

"The worlds first ever spectroscopy enabled iPhone!" Check out our video to see it in action: LINK

Investments in AI will triple in 2017. ($47 billion by 2020 per ) CIO CMO | LINK

Some aspects of fetal development have long puzzled scientists, but new molecular technologies are shining a light: https:/… LINK!

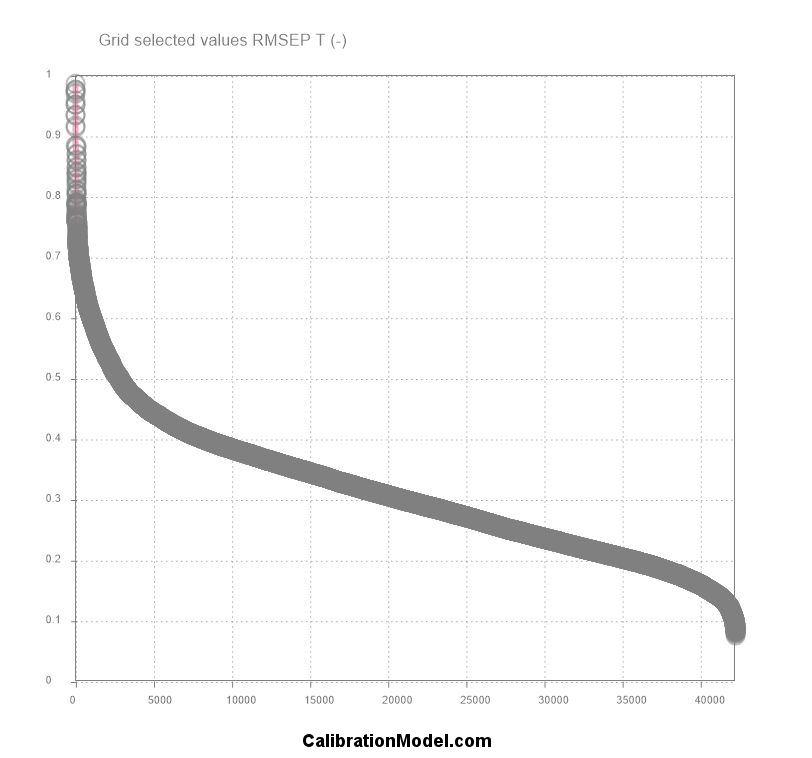

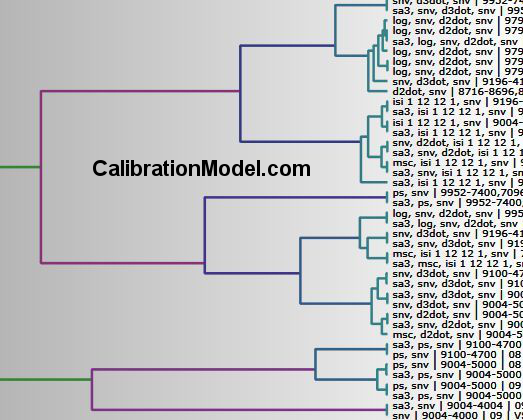

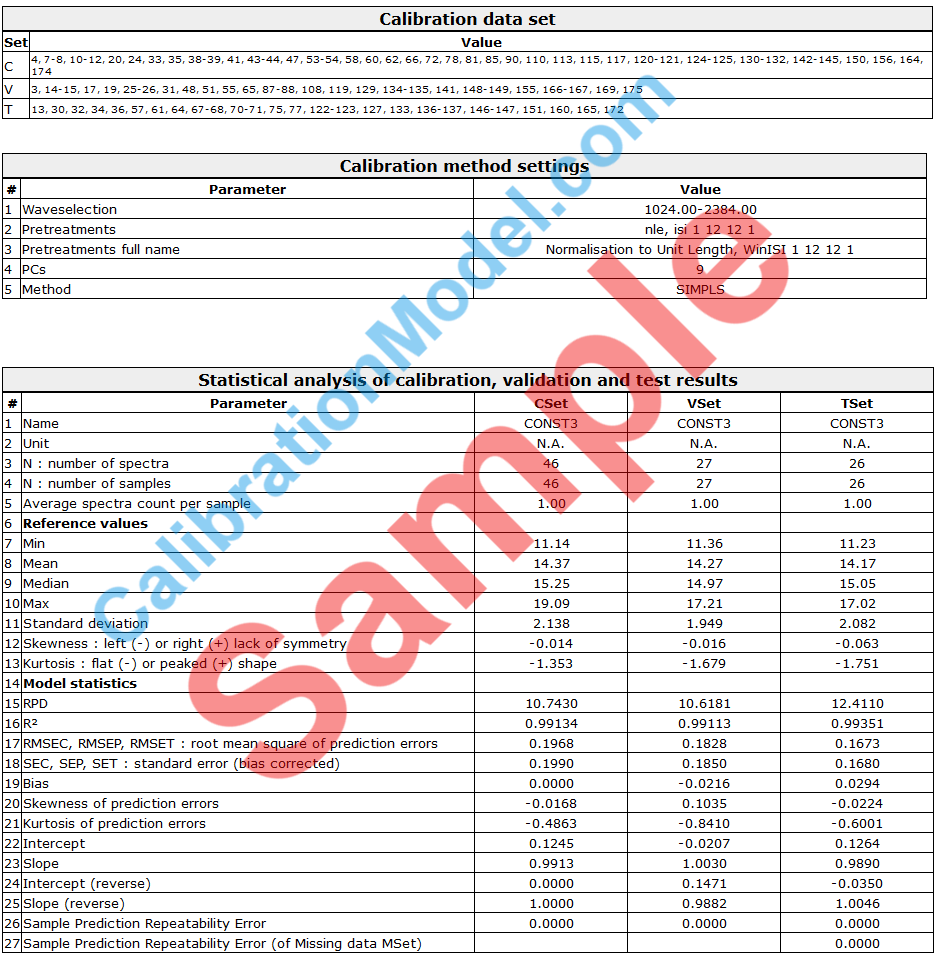

CalibrationModel.com

Spectroscopy and Chemometrics News Weekly 3+4, 2017 | Spectroscopy NIRS MVDA… LINK

Spektroskopie und Chemometrie Neuigkeiten Wöchentlich 3+4, 2017 | NIRS Spektroskopie Chemometrie Multivariate LINK

Spettroscopia e Chemiometria Weekly News 3+4, 2017 | NIRS Spettroscopia Chemiometria news LINK

WHITE PAPER: A novel knowledge-based Chemometric Software Framework for quantitative NIRS Calibration Modeling LINK

Improve Accuracy of fast non-destructive NIR Measurements by Optimal Calibration | spectroscopy sensor modeling LINK

NIRS as a secondary method requires extensive calibration on an ongoing basis | foodindustry Digitalization IoT LINK

Services for Optimization of Chemometric Application Methods of Near-Infrared Spectroscopy | Quality Control NIRS LINK

► Timesaving NIRS Calibration ► near-infrared spectroscopy | protein fat moisture sensor measurement scanning LINK

Chemometrics

Non-Destructive Sensor-Based Prediction of Maturity and Optimum Harvest Date of Sweet Cherry Fruit | sensors LINK

IDC unveils its Top 10 Predictions for global Robotics Industry Industry40 Robotics LINK

Spectroscopy

Global Molecular Spectroscopy Market is expected to reach USD 6.712 billion till 2024. htt… LINK!

Near Infrared

Assessing pre-harvest sprouting in cereals using near-infrared spectroscopy-based metabolomics LINK

Rapid screening of commercial extra virgin olive oil products for authenticity: Performance of a handheld NIR device LINK

Hyperspectral

Imec () launches TDI, multispectral and hyperspectral sensors | imaging HSI LINK

Near-infrared hyperspectral imaging of lamination and finishing processes in textile technology LINK

Spectral Imaging

Viavi Solutions and ESPROS Photonics Corporation Debut New Miniaturized Spectral Sensor and Multispectral Sensor LINK

Equipment

Meta-lenses bring benchtop performance to small, hand-held spectrometer - Science Daily LINK

Scan anywhere with Neospectra Spectrometer Case powered by XPNDBLS PhotonicsWest … LINK!

Agriculture

World feed production exceeds 1 billion MT LINK

Chemometric soil analysis on the determination of specific bands for the detection of magnesium & potassium by ... LINK

Other

This app uses spectral analysis to analyze objects and their makeup HawkSpex LINK

Research details developments in the multivariate analysis software industry | MVA LINK

"The worlds first ever spectroscopy enabled iPhone!" Check out our video to see it in action: LINK

Investments in AI will triple in 2017. ($47 billion by 2020 per ) CIO CMO | LINK

Some aspects of fetal development have long puzzled scientists, but new molecular technologies are shining a light: https:/… LINK!

CalibrationModel.com

Spectroscopy and Chemometrics News Weekly 3+4, 2017 | Spectroscopy NIRS MVDA… LINK

Spektroskopie und Chemometrie Neuigkeiten Wöchentlich 3+4, 2017 | NIRS Spektroskopie Chemometrie Multivariate LINK

Spettroscopia e Chemiometria Weekly News 3+4, 2017 | NIRS Spettroscopia Chemiometria news LINK

WHITE PAPER: A novel knowledge-based Chemometric Software Framework for quantitative NIRS Calibration Modeling LINK

Improve Accuracy of fast non-destructive NIR Measurements by Optimal Calibration | spectroscopy sensor modeling LINK

NIRS as a secondary method requires extensive calibration on an ongoing basis | foodindustry Digitalization IoT LINK

Services for Optimization of Chemometric Application Methods of Near-Infrared Spectroscopy | Quality Control NIRS LINK

► Timesaving NIRS Calibration ► near-infrared spectroscopy | protein fat moisture sensor measurement scanning LINK

Chemometrics

Non-Destructive Sensor-Based Prediction of Maturity and Optimum Harvest Date of Sweet Cherry Fruit | sensors LINK

IDC unveils its Top 10 Predictions for global Robotics Industry Industry40 Robotics LINK

Spectroscopy

Global Molecular Spectroscopy Market is expected to reach USD 6.712 billion till 2024. htt… LINK!

Near Infrared

Assessing pre-harvest sprouting in cereals using near-infrared spectroscopy-based metabolomics LINK

Rapid screening of commercial extra virgin olive oil products for authenticity: Performance of a handheld NIR device LINK

Hyperspectral

Imec () launches TDI, multispectral and hyperspectral sensors | imaging HSI LINK

Near-infrared hyperspectral imaging of lamination and finishing processes in textile technology LINK

Spectral Imaging

Viavi Solutions and ESPROS Photonics Corporation Debut New Miniaturized Spectral Sensor and Multispectral Sensor LINK

Equipment

Meta-lenses bring benchtop performance to small, hand-held spectrometer - Science Daily LINK

Scan anywhere with Neospectra Spectrometer Case powered by XPNDBLS PhotonicsWest … LINK!

Agriculture

World feed production exceeds 1 billion MT LINK

Chemometric soil analysis on the determination of specific bands for the detection of magnesium & potassium by ... LINK

Other

This app uses spectral analysis to analyze objects and their makeup HawkSpex LINK

Research details developments in the multivariate analysis software industry | MVA LINK

"The worlds first ever spectroscopy enabled iPhone!" Check out our video to see it in action: LINK

Investments in AI will triple in 2017. ($47 billion by 2020 per ) CIO CMO | LINK

Some aspects of fetal development have long puzzled scientists, but new molecular technologies are shining a light: https:/… LINK!

CalibrationModel.com

Spectroscopy and Chemometrics News Weekly 3+4, 2017 | Spectroscopy NIRS MVDA… LINK

Spektroskopie und Chemometrie Neuigkeiten Wöchentlich 3+4, 2017 | NIRS Spektroskopie Chemometrie Multivariate LINK

Spettroscopia e Chemiometria Weekly News 3+4, 2017 | NIRS Spettroscopia Chemiometria news LINK

WHITE PAPER: A novel knowledge-based Chemometric Software Framework for quantitative NIRS Calibration Modeling LINK

Improve Accuracy of fast non-destructive NIR Measurements by Optimal Calibration | spectroscopy sensor modeling LINK

NIRS as a secondary method requires extensive calibration on an ongoing basis | foodindustry Digitalization IoT LINK

Services for Optimization of Chemometric Application Methods of Near-Infrared Spectroscopy | Quality Control NIRS LINK

► Timesaving NIRS Calibration ► near-infrared spectroscopy | protein fat moisture sensor measurement scanning LINK