that performs better than the one in an research paper that states :

- “Readers are encouraged to use this big data set and produce innovative ideas and algorithms to achieve RMSEP better than 0.79%.”

Chemometric software competitions (aka shootouts) are a good way to check algorithms, software and knowledge against all other experts in the field.

Imagine that the prediction results can be produced with any kind of software and newest algorithms.

And we just use PLS right to generate models that can be used on all NIR software systems, because PLS is a quasi standard, supported in all major chemometrics software.

Our software framework reached very good results, got gold (rank #1) and silver (rank #2) during well known international NIR Chemometric software shootouts* so far, the competitions are held bi-annual.

| Rank / competitors | Competition / Conference | Year |

| #1 / 1 ** | Kaji / ANSIG | 2014 |

| #1 / 150 | Kaji / ANSIG | 2012 |

| #2 / ??? | IDRC / IDRC | 2012 |

A set of NIR spectral data will be available for downloading from the ANISG website and contestants will be asked to find and explain a "best" chemometric model to robustly predict samples of the same type.

A panel will select the three "best" entries based on the predicted results and spectroscopic explanation of the products and attributes of interest.

http://www.anisg.com.au/the-kaji-competition

The IDRC Competition

The Software Shootout has been a staple of the IDRC. It is a competition amongst participants of the conference that aims at determining the person who developed the best model and obtained the lowest prediction error for a particular problem.

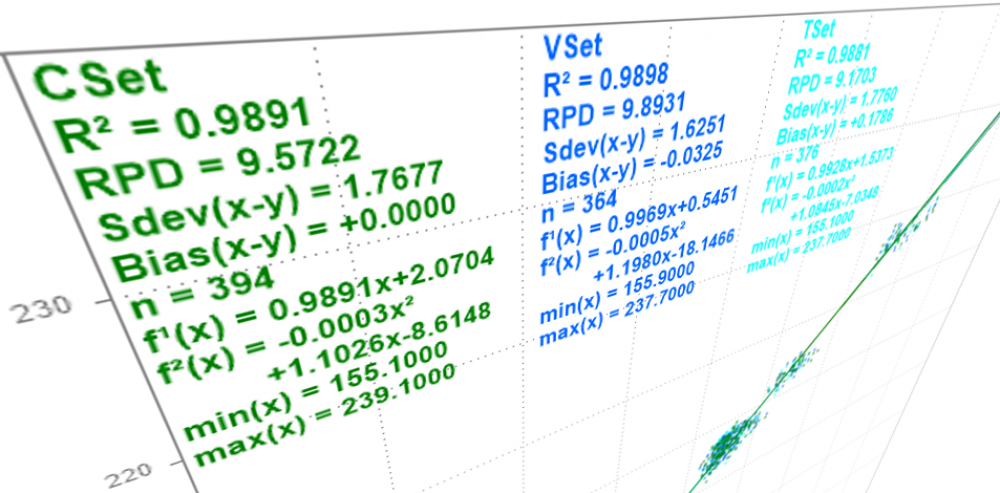

Every IDRC, a new challenge is proposed to participants. The challenge consists of a data set with calibration, test and a validation set.

Participants are given target values for the calibration and test sets but must do their best to develop a model that will predict the validation set as accurately and precisely as possible. Challenges from all sorts of fields of NIRS have been used (agriculture, biomedical, pharmaceutical, soil, …).

IDRC

*) The author was unable to present the results at the conferences, so this ranking was not official but confirmed by the shootout organizers. Thanks go to Benoit Igne, IDRC 2012 shootout organizer and Steve Holroyd, Kaji Competition organizer at ANISG Conference 2012.

Conclusion

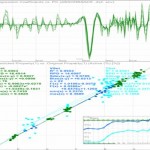

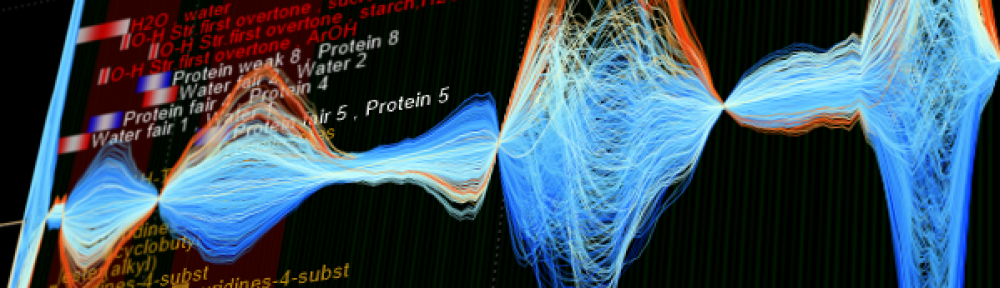

Our chemometric software framework can significantly reduce the time spent for NIR method development and fine optimization. The time saving can be achieved through highly automated experiments and the usage of cloud computing. Calibrations are built and evaluated using automated good practices protocols resulting in useful, precise and robust Calibrations. The high number of experiments enables a deep screening of the solution domain to find the optimum calibration settings, something currently unavailable in standard chemometric software.

**) We were the only participator that got the 4 competition tasks (4-times more than usual) completed in that short time and submitted the fully documented results. After the competition, the information was given, that the data was originated from forages and the constituents were dry matter, organic matter digestibility, protein and ash. Thanks go to Daniel Cozzolino, Kaji 2014 Competition organizer.

In 2021 we automatically calibrated Mango DM with RMSEP = 0.7247 with our software

that performs better than the one in an research paper that states :

- “Readers are encouraged to use this big data set and produce innovative ideas and algorithms to achieve RMSEP better than 0.79%.”

Chemometric software competitions (aka shootouts) are a good way to check algorithms, software and knowledge against all other experts in the field.

Imagine that the prediction results can be produced with any kind of software and newest algorithms.

And we just use PLS right to generate models that can be used on all NIR software systems, because PLS is a quasi standard, supported in all major chemometrics software.

Our software framework reached very good results, got gold (rank #1) and silver (rank #2) during well known international NIR Chemometric software shootouts* so far, the competitions are held bi-annual.

| Rank / competitors | Competition / Conference | Year |

| #1 / 1 ** | Kaji / ANSIG | 2014 |

| #1 / 150 | Kaji / ANSIG | 2012 |

| #2 / ??? | IDRC / IDRC | 2012 |

A set of NIR spectral data will be available for downloading from the ANISG website and contestants will be asked to find and explain a "best" chemometric model to robustly predict samples of the same type.

A panel will select the three "best" entries based on the predicted results and spectroscopic explanation of the products and attributes of interest.

http://www.anisg.com.au/the-kaji-competition

The IDRC Competition

The Software Shootout has been a staple of the IDRC. It is a competition amongst participants of the conference that aims at determining the person who developed the best model and obtained the lowest prediction error for a particular problem.

Every IDRC, a new challenge is proposed to participants. The challenge consists of a data set with calibration, test and a validation set.

Participants are given target values for the calibration and test sets but must do their best to develop a model that will predict the validation set as accurately and precisely as possible. Challenges from all sorts of fields of NIRS have been used (agriculture, biomedical, pharmaceutical, soil, …).

IDRC

*) The author was unable to present the results at the conferences, so this ranking was not official but confirmed by the shootout organizers. Thanks go to Benoit Igne, IDRC 2012 shootout organizer and Steve Holroyd, Kaji Competition organizer at ANISG Conference 2012.

Conclusion

Our chemometric software framework can significantly reduce the time spent for NIR method development and fine optimization. The time saving can be achieved through highly automated experiments and the usage of cloud computing. Calibrations are built and evaluated using automated good practices protocols resulting in useful, precise and robust Calibrations. The high number of experiments enables a deep screening of the solution domain to find the optimum calibration settings, something currently unavailable in standard chemometric software.

**) We were the only participator that got the 4 competition tasks (4-times more than usual) completed in that short time and submitted the fully documented results. After the competition, the information was given, that the data was originated from forages and the constituents were dry matter, organic matter digestibility, protein and ash. Thanks go to Daniel Cozzolino, Kaji 2014 Competition organizer.

In 2021 we automatically calibrated Mango DM with RMSEP = 0.7247 with our software

that performs better than the one in an research paper that states :

- “Readers are encouraged to use this big data set and produce innovative ideas and algorithms to achieve RMSEP better than 0.79%.”

Chemometric software competitions (aka shootouts) are a good way to check algorithms, software and knowledge against all other experts in the field.

Imagine that the prediction results can be produced with any kind of software and newest algorithms.

And we just use PLS right to generate models that can be used on all NIR software systems, because PLS is a quasi standard, supported in all major chemometrics software.

Our software framework reached very good results, got gold (rank #1) and silver (rank #2) during well known international NIR Chemometric software shootouts* so far, the competitions are held bi-annual.

| Rank / competitors | Competition / Conference | Year |

| #1 / 1 ** | Kaji / ANSIG | 2014 |

| #1 / 150 | Kaji / ANSIG | 2012 |

| #2 / ??? | IDRC / IDRC | 2012 |

A set of NIR spectral data will be available for downloading from the ANISG website and contestants will be asked to find and explain a "best" chemometric model to robustly predict samples of the same type.

A panel will select the three "best" entries based on the predicted results and spectroscopic explanation of the products and attributes of interest.

http://www.anisg.com.au/the-kaji-competition

The IDRC Competition

The Software Shootout has been a staple of the IDRC. It is a competition amongst participants of the conference that aims at determining the person who developed the best model and obtained the lowest prediction error for a particular problem.

Every IDRC, a new challenge is proposed to participants. The challenge consists of a data set with calibration, test and a validation set.

Participants are given target values for the calibration and test sets but must do their best to develop a model that will predict the validation set as accurately and precisely as possible. Challenges from all sorts of fields of NIRS have been used (agriculture, biomedical, pharmaceutical, soil, …).

IDRC

*) The author was unable to present the results at the conferences, so this ranking was not official but confirmed by the shootout organizers. Thanks go to Benoit Igne, IDRC 2012 shootout organizer and Steve Holroyd, Kaji Competition organizer at ANISG Conference 2012.

Conclusion

Our chemometric software framework can significantly reduce the time spent for NIR method development and fine optimization. The time saving can be achieved through highly automated experiments and the usage of cloud computing. Calibrations are built and evaluated using automated good practices protocols resulting in useful, precise and robust Calibrations. The high number of experiments enables a deep screening of the solution domain to find the optimum calibration settings, something currently unavailable in standard chemometric software.

**) We were the only participator that got the 4 competition tasks (4-times more than usual) completed in that short time and submitted the fully documented results. After the competition, the information was given, that the data was originated from forages and the constituents were dry matter, organic matter digestibility, protein and ash. Thanks go to Daniel Cozzolino, Kaji 2014 Competition organizer.